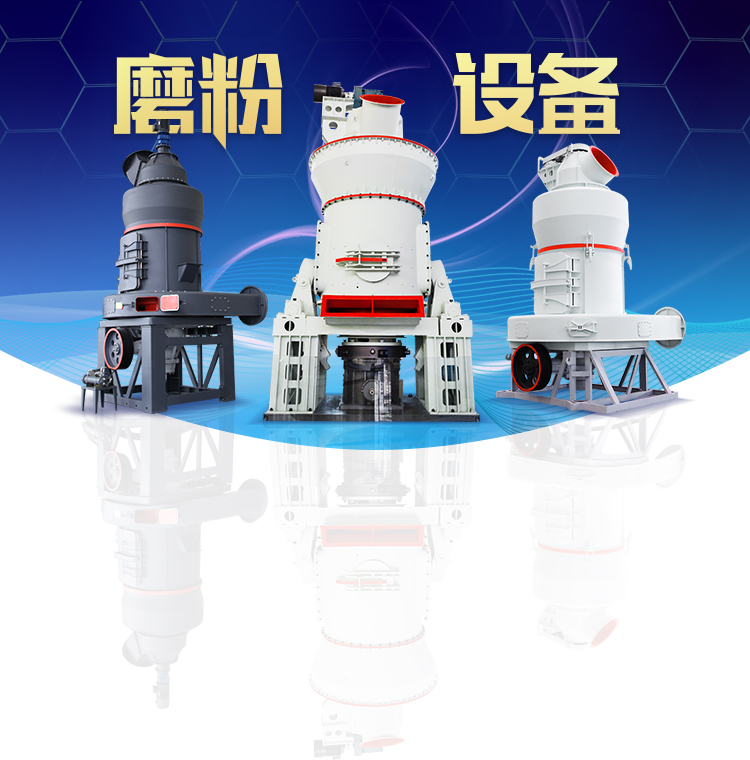

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Crusher Working Detailsjaw

.jpg)

Jaw Crusher Basics in 3 MinutesSBM Industrial

2024年12月10日 This article presents a comprehensive comparison between jaw crusher, impact crusher and cone crusher, highlighting their differences in terms of structure, working principles, crushing capabilities, and applications2024年11月27日 What is a Jaw Crusher? The Working Principle of a Jaw Crusher Crushing Motion and Mechanism; Jaw Crusher Components; Types of Jaw Crushers SingleToggle Jaw Crusher Working Principle: An InDepth Guide2024年6月28日 A jaw crusher is a type of mechanical equipment that is used in the mining and construction industry to crush rocks and large materials into smaller pieces The jaw crusher How Does a Jaw Crusher Work?SBM Industrial Technology 2023年10月16日 Understanding the jaw crusher working principle can help inform operations and optimizations, leading to better overall performance in your aggregate processing plant In The Mechanics of Crushing: Understanding the Jaw Crusher Working

The Principle, Construction, Working, and

Principle: The working principle of a jaw crusher is based on the movement of a toggle plate that is connected to a pivot point at the top of the crusher When the toggle plate moves, it causes the movement of the jaw, which in turn causes Working Principle: The electric motor drives Vbelt to make the swing jaw up and down through eccentric shaft When the swing jaw goes up, the angle between toggle plate and swing jaw Working Principle and Feature of Jaw Crusher – Luoyang 2022年1月14日 Commonly used crushers include jaw crusher, impact crusher, hammer crusher, cone crusher, etc This article will introduce the working principles of these four types of crushing machines one by one to help you Working Principle of 4 Commonly Used Crushers This article will provide a detailed analysis of its working principle and structure 1、 Working principle: The jaw crusher mainly crushes materials through the friction and crushing action of Working principle and structural analysis of jaw crusher

The Construction and Working Principle of Jaw Crusher

The working principle of a jaw crusher is based on the mechanical pressure generated by the movement of its jaw plates When the moving jaw plate moves towards the static jaw plate, the 2022年2月22日 A jaw or toggle crusher consists of a set of vertical jaws, one jaw being fixed and the other being moved back and forth relative to it by a cam or pitman mechanism The jaws are farther apart at the top than at the bottom, Jaw Crusher: Range, Working Principle, Contribute to luoruoping/id development by creating an account on GitHubid/16/detail crusher cadmd at main luoruoping/id GitHub2024年12月9日 The Crusher is a machine added by Mekanism and grinds solid materials into dusts However, it does not double ores It is used primarily for two tasks: producing Bio Fuel and being an important part of the tier 2, 3 and 4 oreprocessing system (see below) The Crusher is also used as a component in crafting the Basic Crushing Factory and its more advanced Crusher (Mekanism) Official Feed The Beast Wiki

How does a Rock Crusher Work Jaw Crusher

2021年11月22日 Jaw crushers include Superior, Type “B” Blake, FineReduction, and Dodge — sizes, 4 by 6 to 84 by 66 inchesA reciprocating machine, the crushes material in a straight line between jaws — without Contribute to lbsid/en development by creating an account on GitHuben/169/jaw crusher detailsstonemd at main lbsid/enPrinciples Of A Stone Crusher spitsid Basic Principle Of Stone Crusher cone crushers device and principle of work ecuador working principle of cone mobile crusher Manufacturer zyc cone crusher,this page is mainly about the working principle of stone crushers principles of working india aterial Feeding: Raw materials are fed into the jaw crusher from the top opening This is typically done with the help of a vibrating feeder, which ensures that the material is fed at a constant rate Crushing Chamber: Inside the crusher, there are two jaws – a fixed jaw and a moving jaw The fixed jaw is stationary while the moving jaw how jaw crusher working zenithmineral

Crusher (Immersive Engineering) Official Feed The Beast Wiki

5 天之前 This page is about the Crusher added by Immersive Engineering For other uses, see Crusher The Crusher is a 3×5×3 multiblock added by Immersive Engineering It is used for crushing ores into grit, which is more efficient than normal smelting Once the blocks are assembled, use the Engineer's Hammer on the center of the front of the longer side (which Sandvik QJ341 mobile jaw crusher features a 1,200 x 750mm (47 x 29 in) jaw opening, built to tackle the most difficult applications with ease It has been designed to meet the needs of the operator seeking a high performance mobile jaw crusher which is both reliable and durableCrusher Works Quality Mobile Crushers, Screens,2023年12月26日 There is power (full 32 kFE) and levered to ON, but the Crusher is not crushing cobble stone blocks (nor any other blocks), not any ores, and jumping into it does not even harm me I tested the Crusher out both on Crusher does not work Issue #5830 BluSunrize 2023年2月23日 A cone crusher is a powerful tool used in the mining, aggregate, and construction industries to crush materials into smaller pieces But how does it work? In this article, we'll explore the cone crusher working principle, including the eccentric motion of the main shaft, the crushing process, and the importance of proper maintenance Whether you're a seasoned Understanding the Cone Crusher Working Principle: How It

en/123/jaw crusher md at main dinglei2022/en

Write better code with AI Security Find and fix vulnerabilities2 Both the structure and working of a jaw crusher are quite simple 3 The product size is quite small and can range up to millimetres 4 Repair and maintenance of a jaw crusher are convenient and easy 5 The reliability of a jaw crusher is significantly high 6 The broken parts of the jaw crusher are easy to replace Disadvantages of a Jaw Jaw Crusher Working Principle StudiousGuy2018年12月26日 working of the crusher is as under The main shaft of the crusher is journaled in the spider bearing and in the eccentric bearing assembly The spider bearing fixes the position of the upper end of the main shaft Eccentric bearing assembly with inner bushing can be replaced, or in some models turned, to adjustConstruction, Working and Maintenance of Practical cone crusher,spring cone crusher,cone crusher working principle Spring Cone Crusher Working Principle Driven by the electricmotor ,the eccentric shaft bush will rotate with the triangle belt,small and big bevel gear,big bear Cone Crusher Working Principle

The Mechanics of Crushing: Understanding the Jaw Crusher Working

2023年10月16日 After understanding the jaw crusher working principle, we need to know some maintenance tips Maintaining your jaw crusher is crucial for its optimal performance and longevity The first step is regular inspection Check the machine daily for any signs of wear or damage This practice helps you catch issues early before they become major problems2024年7月2日 Crusher working process Free download as PDF File (pdf) or read online for freeCrusher Working Process PDF Scribd2014年12月9日 18 • Single Toggle Jaw Crusher • In the single toggle jaw crushers, the swing jaw is suspended on the eccentric shaft which leads to a much more compact design than that of the double toggle jaw crusher • The swing jaw, suspended on the eccentric, undergoes two types of motion swing motion towards the fixed jaw due to the action of toggle plate and vertical Jaw crusher PPT SlideShare2019年1月10日 1 PARTICULATE TECHNOLOGY (PRACTICAL) TRAINER: MIR MUHAMMAD BOZDAR MAZHAR SHAFI 17CH10 CRUSHER: A crusher is a multi dimensional machine which is designed to reduce large size materials into smaller size materials Crushers may be used to reduce the size, or change the form of waste materials so they can be more easily disposed of Crusher and Its Types PDF SlideShare

)D`ERF`389RMI4.jpg)

crusherwork:20000

crusherwork:20000 发送2019年4月8日 Six crusher plant sites were selected based on their varying production capacity for the study Accordingly, selected sites were visited to carry out area noise and wholebody vibration surveysNoise and Vibration Control in Crusher Plant Activities to Enhance 2015年6月23日 Test Procedures for the Characterization of Crusher Performance The Bond Impact Work Index method has been an industry standard for the determination of crusher power requirements but was originally developed to ensure, that sufficient power was connected to primary gyratory crushers In this method, pieces of rock are fractured by trial and Impact Crusher Working Principle 911Metallurgist4 天之前 Jaw Crushers Designed to crush ROM feed material for demanding quarrying, mining, and demolition purposes With their unique Elliptical motion of the swing jaw Crushers, ensure highly efficient production rates at any settingJaw Crushers Manufacturer in India Puzzolana

.jpg)

id/16/detail crusher cadmd at main luoruoping/id GitHub

Contribute to luoruoping/id development by creating an account on GitHub2024年12月9日 The Crusher is a machine added by Mekanism and grinds solid materials into dusts However, it does not double ores It is used primarily for two tasks: producing Bio Fuel and being an important part of the tier 2, 3 and 4 oreprocessing system (see below) The Crusher is also used as a component in crafting the Basic Crushing Factory and its more advanced Crusher (Mekanism) Official Feed The Beast Wiki2021年11月22日 Jaw crushers include Superior, Type “B” Blake, FineReduction, and Dodge — sizes, 4 by 6 to 84 by 66 inchesA reciprocating machine, the crushes material in a straight line between jaws — without How does a Rock Crusher Work Jaw CrusherContribute to lbsid/en development by creating an account on GitHuben/169/jaw crusher detailsstonemd at main lbsid/en

.jpg)

stone crushers principles of working india kooksco

Principles Of A Stone Crusher spitsid Basic Principle Of Stone Crusher cone crushers device and principle of work ecuador working principle of cone mobile crusher Manufacturer zyc cone crusher,this page is mainly about the working principle of Material Feeding: Raw materials are fed into the jaw crusher from the top opening This is typically done with the help of a vibrating feeder, which ensures that the material is fed at a constant rate Crushing Chamber: Inside the crusher, there are two jaws – a fixed jaw and a moving jaw The fixed jaw is stationary while the moving jaw how jaw crusher working zenithmineral

水式矿石磨粉机

--工业磨机

--高钙粉的材质

--酸生石灰活性埃洛石

--汽车截式一体碳酸钙磨粉机

--立方和KG换算

--内蒙古达拉特旗矿石制粉厂

--生石灰高岭土垫层套定额

--研磨机能破电石吗

--矿石磨粉机email

--工业磨粉机厂家整改方案资质

--上海镭蒙磨粉机

--山东边角料采用制粉加工项目节能改造

--泡沫混凝土机

--方解石粉市场需求分析方解石粉市场需求分析方解石粉市场需求分析

--沖生石灰照片機械

--方解石矿的开采过程

--生产矿井每千米掘进进尺需要多少投资生产矿井每千米掘进进尺需要多少投资生产矿井每千米掘进进尺需要多少投资

--辉长岩制粉设备

--重庆碳酸钙加工机械多少钱一台

--山西*矿石磨粉机石灰石

--生石灰形粉碎机

--山石磨粉机械

--超音波研磨机

--复合肥滚筒粉磨系统机

--上海世帮粉体机械制造有限公司

--生石灰石灰石粉碎机的计算

--办理爆破公司简介

--灰石灰石砖厂成套设备

--叶腊岩预粉磨砂粉立磨精品砂粉设备价格,生产厂家有哪些

--